Internal Partition

There are many factors that can influence the acoustic performance of a robustdetails® separating floor – some less obvious than others. For example, internal partitions (the walls between rooms within a single dwelling) could be built to fully meet the acoustic performance of Building Regulation Requirement E2, yet if not installed correctly, they can have direct effect on the performance of the floor.

Joisted floors

For the lightweight (timber or steel) separating floors, specific sections are provided in the Robust Detail to show how the junctions at both the head and base of the partition are to be formed.

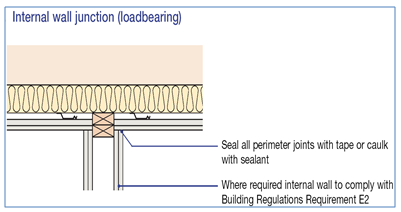

By their nature, loadbearing partitions have to be fixed to the structural floor elements, so this means they will need to pass through the ceiling lining.

To prevent sound bypassing the ceiling lining via the partition, the junction is blocked as shown in the diagram; and the joint of the wall board to ceiling lining is sealed.

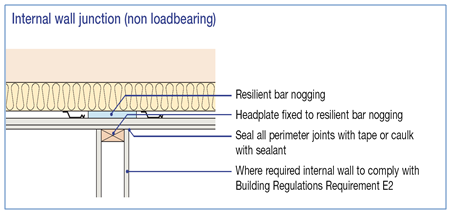

A non-loadbearing partition can be fitted through the ceiling lining in the same way as the loadbearing partition, provided all joints are sealed and all other relevant guidance is followed; but arguably, allowing the ceiling lining to remain intact would give the more robust solution. As with the ceiling board fixings, it is vital that the screws used to secure the top rail do not go into or touch the joist. Here, a short section of resilient bar (a ‘noggin’ or ‘nogging’) is shown attached to the joist at right-angles to the main resilient bars to provide a fixing point for the partition – but it is essential that the right length of screw is used to avoid contact with the joist. (See our previous Top Tip on Timber and Steel floors for details on resilient bars).

If electrical cables or other services run from the ceiling into the partition, then the penetration in the header plate should be sealed usin flexible sealant.

Partitions may be installed directly off the core floor provided the 5mm (min) resilient flanking strip is correctly installed to all perimeters of the FFT to isolate it from all the walls, wall finishes and skirtings. This will include continuing the isolating edge detail through the internal door openings.

Partitions may also be constructed off the FFT flooring board – although additional battens may be necessary to support the internal walls, so guidance should be sought from the manufacturer.

Concrete floors

For the robustdetails® concrete separating floors, guidance notes about the junction detailing are provided on pages 6 and 7 of Appendix A1 in the Robust Details Handbook.

Whilst the makeup of a concrete floor differs significantly from a lightweight floor, the principles regarding partitions are similar.

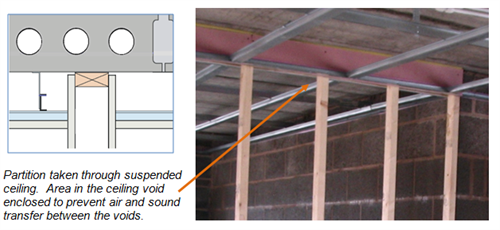

Normally the partition would be attached directly to the soffit of the structural floor, as this gives it better stability – this is permissible within the Robust Details specifications, as long as: the partition is closed off to prevent sound travelling between the partition void and the ceiling void; and the joints of the finishes (and any service penetrations) are sealed.

The header rail of the partition can be fixed directly to the concrete – there is no need to include any resilient material between the two.

If preferred, the partitions may be installed after the suspended ceiling has been put in place. In this case, the partition must only be fixed into the metal frame of the ceiling and not fixed rigidly to the concrete floor structure: e.g. via support beams.

Partitions may be installed directly off the core floor provided that the isolating edge strip that is specified for the Robust Detail adopted, is correctly installed to all perimeters of screed or FFT (according to the Detail), to fully isolate it from all the walls, wall finishes and skirtings. This will include continuing the isolating edge detail through the internal door openings.

Depending on sequencing, partitions may be constructed off the floating screed or FFT. In these instances, the manufacturer of the resilient component needs to confirm that it can support the line loads. When using this method, it is critical that fixings do not penetrate or pass through the resilient layer, as this would bridge the screed to the structural floor creating a transmission path.

Weight for it ...

The lightweight partitions discussed above can be formed using steel or timber but masonry can also be used to construct partitions in conjunction with concrete floors. However, unlike the lightweight partitions, that do not have a weight criterion, the masonry partitions must have a minimum mass per unit area of 120 kg/m2 (including the finish) OR at least that of the approved flanking wall inner leaf, for the separating floor in question, if that is less.

If you have any techncial enquiries please do not hesitate to contact our technical team on 03300 882140 or email: technical@robustdetails.com

Return to the Top Tips page