Get your Back Up to the Wall

If building with timber or light steel frame, there are often occasions when the gypsum board alone is not sufficient to give a secure

If building with timber or light steel frame, there are often occasions when the gypsum board alone is not sufficient to give a secure

fixing for heavier-load items such as kitchen cupboards and Doc.M grab rails – and the stud positions just don’t give the flexibility for where you need to locate the fixings.

At these times, you’ll need to provide a back-up to the wall to give the reinforcement required for the fixtures and fittings.

This is where pattressing comes in.

Pattressing is a layer of (normally) plywood sheet that is applied either to certain areas of the wall, to coincide with the fixtures; or to the complete face of the wall – where this also has the benefit of allowing additional fittings in the future, or options for repositioning.

So, does Ply Comply?

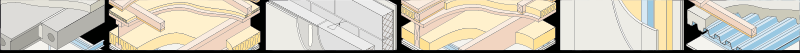

The robustdetails® timber and light steel walls specify “2 or more layers of gypsum-based board both sides”. As ply is not gypsum-based, it cannot be used as a replacement for one of these layers – however, it can be used in addition to the gypsum board layers.

Facing, the facts

Applying the pattressing to the face of the frame, to cover the whole area of wall, is acceptable provided the specified 2 layers of gypsum board are fitted hard against the pattressing, such that there are no voids within the sandwich.

From an acoustics standpoint, the pattressing can also be positioned between the 2 layers of gypsum board, but this may not be as strong to fix to as when it’s applied direct to the frame.

Getting into the Detail

Alternatively, the pattressing can be placed between the studs so it doesn’t add to the overall thickness of the wall – but again, this has to be flush to the face of the studs so there are no voids between this and the gypsum board layers.

The other thing to be mindful of here is that the robustdetails® Handbook. state a density range for the mineral wool insulation that can be fitted within the wall, but the density quoted by the manufacturer is for the material in its free state – excessive compression of the insulation will increase the density. In timber frame, if only the minimum 60mm insulation is fitted between 89mm deep studs, there is plenty of room to fit the pattressing. But if the stud voids are fully-filled, you’ll need to check that the pattressing will not compress the insulation so much that it exceeds the maximum kg/m3 allowed in the Detail – this can be a particular risk where the wall leafs are fully sheathed; or pattressing is back-to-back across a fully-insulated unsheathed wall.