.. and it’s Hi Ho Gypsum Lining

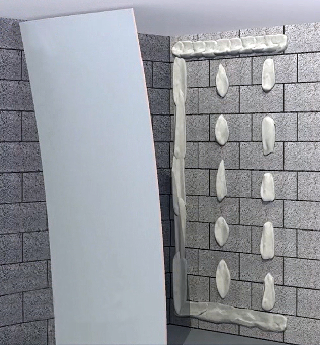

How are boards used on masonry walls?

The robustdetails® masonry separating walls only specify the mass per unit area because mass is the principal consideration; so if 10kg/m2 was specified, builders can decide whether this is achieved through the use of 10mm, 12.5mm or 15mm thick board. Boards are applied to the wall via dabs.

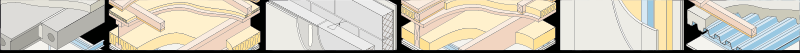

Why are timber and steel frame walls different?

These walls don’t benefit from the core mass associated with masonry, so the performance is dependent on the surface mass of the wall and its bending stiffness. Unlike masonry walls with a single layer of gypsum board, timber and light steel frame walls must have a minimum of two layers on each leaf, with all joints staggered. They are fixed to the studs and outer layer joints taped and filled. These linings are much heavier, ranging from 20 to 32 kg/m2 compared to 8 to 10 kg/m2 for masonry walls.

What about boards in suspended ceilings for concrete separating floors?

The usual method is a metal frame (MF) ceiling system, which gives the required ceiling void depth. Currently, three of these floor types also allow the ceiling treatment to be attached via timber battens – but this can be dependent on the thickness of the structural floor; and could also include the need for resilient fixings, so close attention is needed when reading the specifications. Note that the weight of the gypsum board can vary between the floor types – and even within the same floor type where it has a choice of ceiling treatments.

Why so many boards in light frame separating floors?

All timber floors with a resilient batten floating floor treatment (FFT) must have a layer of nominal 13.5 kg/m2 gypsum board on top of the battens and directly underneath the walking surface. This is to block sound from getting into and out of the batten void.

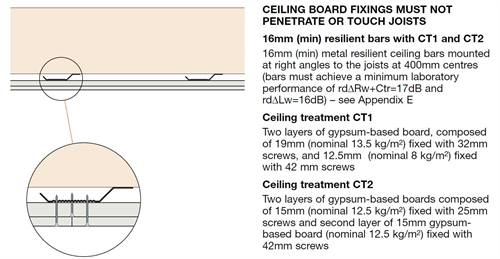

The ceiling linings must be isolated from the structural floor through the use of resilient bars. If the length of ceiling board fixing screw is greater than the board thickness and resilient bar depth combined, then the screw could go into the joist bypassing the resilient bars. To guard against this, the ceiling treatments (CT) for these floors specify a thickness for the gypsum board; and the corresponding screw length for each layer. The board thickness is specified in addition to the weight, and both criteria must be met.

Can’t a different board such as plywood be used instead?

No, just stick with what’s specified. When Robust Details are assessed, it is on the basis of tests conducted on actual walls and floor. Each of the materials used in these makes its own contribution, so when combined they address the full sound spectrum and make an effective barrier.

If you have any techncial enquiries please do not hesitate to contact our technical team on 03300 882140 or email: technical@robustdetails.com

Return to the Top Tips page