Compressive Strength v Density

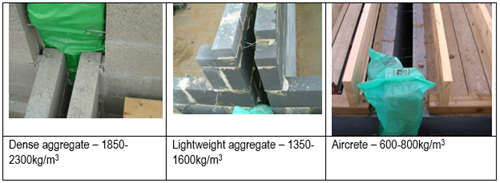

The Robust Details masonry separating wall specifications set clear requirements for the type of blockwork that can be used in the construction. In some cases, they call for a specific product to be used – one that has been tested and assessed for the relevant robustdetails® status. If this isn’t the case, blockwork types are separated into three categories.

- Dense aggregate – with a dry density of 1850-2300kg/m3

- Lightweight aggregate – with a dry density of 1350-1600kg/m3 (otherwise known as medium density)

- Aircrete – with a dry density of 600-800kg/m3.

Blockwork used must be of a type that meets the relevant specification, particularly concerning density. Mass or density is one of the key factors in sound insulation performance, which is why the specifications pay so much attention to it.

However, we are aware that confusion can occur because it’s common in the industry to describe blockwork in terms of compressive strength (3.6N/mm2, 7N/mm2, 10N/mm2…) rather than by blockwork type and dry density.

Compressive strength is obviously relevant to the structural performance of the blockwork - but it has no relevance to the sound insulation performance of the separating wall.

The compressive strength of a block is not directly related to its dry density. Indeed, there are a wide range of options when it comes to considering which block to use. You can get 7N/mm2 blocks in aircrete - medium density and dense aggregate blocks for instance.

When choosing the right block type to use, it’s therefore important to consider the requirements for sound insulation alongside structural performance.

In most cases, it’s likely that there will be a solution that suits in all respects. Occasionally, if structural issues dictate, there might be a need to consider an alternative Robust Details specification so blocks of a suitable compressive strength can be employed.

As a result, if you’re talking to an acoustic consultant, a representative of Robust Details Limited or anyone else interested in sound insulation, it’s a good idea to make sure you know your block type and dry density.

Whilst aircrete and aggregate blocks are easy to distinguish, it’s difficult to be sure of the density of a particular block by sight or by lifting it. Some blocks have identifying marks or paint marks, but to be sure, check the delivery documentation, accompanying literature or ask your supplier.

Another similar point to note is that the blockwork densities are specified in terms of a range:

- Dense aggregate – with a dry density of 1850-2300 kg/m3

- Lightweight aggregate – with a dry density of 1350-1600 kg/m3

- Aircrete – with a dry density of 600-800 kg/m3.

You therefore need to choose a product that fits in the relevant range. It should not be lower or higher (whilst acknowledging normal accepted tolerances).

Often other elements of a robustdetails® s pecification will be specified in terms of a ‘minimum’ requirement. Where details have “minimum” in their specification, it indicates that the value should not be lower than that stated. It does not preclude the use of higher values. For example, where a 75mm (min) cavity size is specified, it does not preclude the use of wider cavities. Similarly, a reference to a wall finish with 8 kg/m2 gypsum-based board does not preclude the use of boards with a greater mass per unit area.

Useful information about block selection can be found via the following web sites:

- The Concrete Block Association - www.cba-blocks.org.uk – for aggregate blocks

- The Aircrete Products Association - www.aircrete.co.uk – for aircrete blocks.

If you have any techncial enquiries please do not hesitate to contact our technical team on 03300 882140 or email: technical@robustdetails.com

Return to the Top Tips page